Six years ago, while attending EuroShop, the global showcase of all things lighting, retail, and tradeshow, I was introduced to “Silicone Edge Fabric Graphics” or “SEG.” At the time, the term was like a glob of peanut butter on the roof of my mouth. Now, Silicone Edge Graphics slides off my tongue like syrup and warm butter. SEG is everywhere. First in trade shows. Then in airports. Now in casual and upscale retailing. It’s inescapable. But why?

Several reasons, but to understand why you need a little background. Not so long ago, all trade show graphics were direct print graphics, mostly on Sintra, Lexan, plexiglass, or heavy stock paper. They were large, expensive to ship, and easily damaged. But, it was what it was and we lived with it. There were some fabric graphics, and the resolution was adequate if you stood 50 yards away from it. Then came early dye-sublimated fabric graphics and the resolution was acceptable from 8-10 yards away.

Around the same time, engineered aluminum extrusions were replacing many panel systems, pop-up displays, and smaller custom wood exhibits. They were durable, modular, design flexible, and easy-to-assemble, and within a few years, “hybrid” displays became a trade show industry category. Hybrids and direct print graphics tolerated one another, but as fabric graphics improved, and boy did they improve, attaching them to hybrids with Velcro and pole-pocket inserts was an easy and logical choice.

Then, a Few Folks Started to Grumble

They didn’t like the appearance of aluminum extrusion. “What,” they

asked, “could be done to minimize the look of an aluminum hybrid display

while retaining its modularity?” Now, here’s where we get to the

fun part. Someone had an epiphany.

“Why not sew a flat piece of silicone to the edge of the fabric and then

insert it into a narrow groove around the perimeter of the aluminum

frame? This would hide the aluminum without compromising the structural

integrity of the display.”

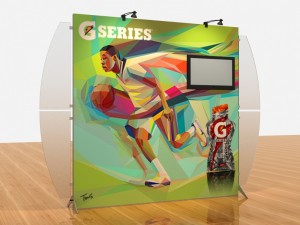

Today, silicone edge graphics come in all shapes and sizes, from

basic squares to rectangles. There are circles and ovals and amoeba

shapes. Now it’s even possible to create large backlit graphics where

the only visible metal is a 1/8” perimeter. Remarkable.

So, why should you consider Silicone Edge Fabric Graphics?

- Vibrant Colors — Often approaching photographic quality.

- Easy Installation – There’s no guesswork. The graphic fits the aluminum frame.

- Carefree and Lightweight – Roll it or fold it. It can even be washed.

- Cost-effective – Once you own the frame, replacing

graphics for a new campaign is more cost-effective than direct print

graphics (and cheaper to ship). - Durable – Unlike direct print graphics, the fabric doesn’t ding, peel, or dent.

Still a little confused. See the video below that demonstrates how to

install SEG. For over 50 examples of trade show displays with SEG, see

the

SEGUE Hybrid Display line on our website.

Written by:

Mel White

Trade show display expert and leader in the industry for over 15 years.